Pintotecno is a diversified services company

for industrial and mobile, focused on

hydraulics components.

Our development is made of cleverness and

speed, grounded on opportunities.

When the company starts a new journey, it

takes it to the end: if the opportunity is

concrete you will see it completely achieved.

We are led by a pure entrepreneurial spirit.

Pintotecno appeal towards multinational

companies relies on pragmatism, robustness

and skill to act quickly.

We are living the 3rd phase of our 40 years

history, the so-called "company expansion".

We expect a steady growth of +20% of

revenues in the next 3 years, along with a

significant improvement of productivity,

due to a new factory system implementation:

more automation, more integration and a new

labour organization.

We aim at building a real customer intimacy, guided

by the principles of one-to-one relation.

Our Program Management unit is in charge of orders

management (from scheduling to execution), while

the Customer Care deals with all the possible issues

related to our products and services, in terms

of Quality and

On Time Delivery (defects, material and documentati

on).

Besides that we are willing to expand our services

portfolio to product and process development,

subsystems manufacturing and management of

supply chain components.

Following the customers needs and expectations we

strive to ensure flexibility and quality,

uncompromisingly.

We consider investments in know-how as strategic.

Our belief in innovation is leading us, and we rely on

building an ecosystem based on shared knowledge.

50% of the new Ginestra site offices area is dedicated

to Industry 4.0 culture dissemination, in order

to create a learning environment open to other

companies, startups and universities

(through courses, labs, internships), following the

traditional social commitment of our company.

Covered Area

Equipment

Products

Batch production

Up to 18 shifts / week

Covered area (available 15.000 sq.m)

Equipment

Products

Highly flexible flow production

Up to 20 shifts / week

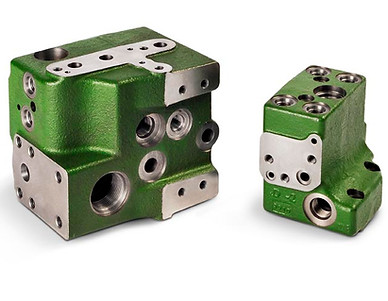

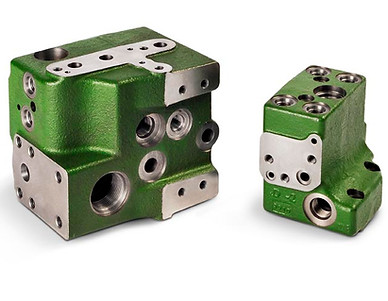

Our design capability is based on three

pillars:

We are able to work with different materials

(aluminium, steel, cast iron), either from bars

or castings.

We deliver the end product to the customer,

taking care of the whole supply chain (from

the foundry to the surface and heat

treatments).

The production system is demand driven.

It allows to meet all the customer needs

(from low to high volumes) applying

differentiated strategies to the production

capacity itself: from in flow dedicated

machines to integrated flexible systems (FMS)

specifically designed for low volumes

production.

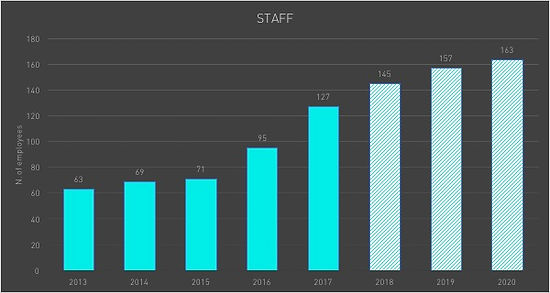

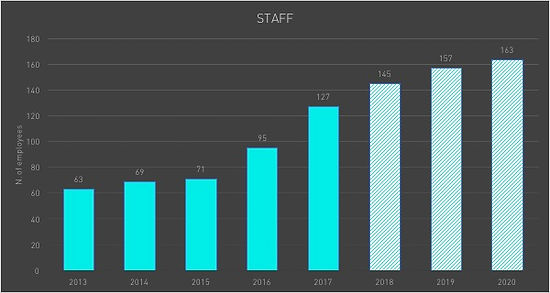

Pintotecno workers are linked to the area where they live. They

express a sense of community that eases the shift of expertise and

new colleagues integration as well.

The inter-generational transition from the founders to the new

management team has encouraged the growth and the company

transformation.

The founders have been passing along core values like "trust"

and “putting the hard work”, as a legacy to the newer

generation that is leading the organization today.

The team of managers and professional leaders is young (33

years old on average), with a top education al level.

Selected because of excellent learning skills and a

high level of acceptance for the changes.

We are performance driven.

Technology and digital culture is in

our DNA, making us naturally geared to innovation.